ダウンロード

- 3 coupling options

- Different materials: aluminum, stainless steel or composite material

- Accessories

- EMI/RFI protection

- Compatible with the main circular connector standards

- Lightweight

- Environmental

主要な特徴と利点

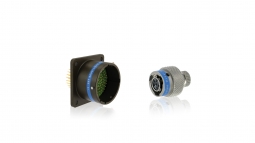

M85049 Backshells

The AS85049 series regroups all our military standard QPL backshells. AS85049 backshells are designed to fit the main circular connectors used in our industry (MIL-DTL-26482 series II, 83723 series 1 & 3, 38999 Series I, II, III & IV); they are qualified for aluminum, stainless steel or composite material (many plating proposed).

Two self-locking technologies were developed: a detented system and the SUNBANK Self-seating mechanism that exceeds the vibration requirements. A free rotatable coupling is also available.

Qualified for multiple EMI/RFI designs, AS85049 SUNBANK backshells are available in banding and crimping platforms for overall shielding, dual EMI ring for overall and individual shielding. The D38999 backshells' bodies are specifically designed to optimize weight and robustness, and the self-seating locking option offers lighter weight and lower profile backshells than a detented system.

SUNBANK offers AS85049/128 qualified bands as well as AS85049/93 shield support rings. Tools are also available to terminate your wiring assembly.

Backshells can be ordered with various interfaces depending on the connector used. Both American and European standards are covered, such as D38999, M26482, EN2997, EN3645, M5015, etc.

A wide range of SUNBANK backshells provide waterproofing and environmental sealing withstanding most severe shock, vibration, cable pullout and external bending moment. SUNBANK part numbers will start with the M85049 appellation.

Technical Data

- Multi configurations: straight, 45°, 90°

- Plating: nickel, cadmium, zinc nickel, black anodized, passivate (for stainless steel only)

- Temperature range:

- Electroless nickel: -65 to +200°C

- Passivate: -65 to +200°C

- Other platings: -65 to +175°C

- Shell conductivity:

- Aluminum: R < 2.5 mΩ

- Composite: R < 2.5 mΩ

- Stainless steel: R < 5 mΩ

- Marking in accordance with MIL-STD-1285

- Salt spray resistance:

- Aluminum shell:

- Electroless nickel : 96 hours

- Black anodize: 500 hours

- Cadmium: 1000 hours

- Zinc nickel: 1000 hours

- Stainless steel shell:

- Passivate: 1000 hours

- Composite shell:

- Electroless nickel: 2000 hours

- Cadmium: 2000 hours

- Zinc nickel: 2000 hours

- Aluminum shell:

Build a Backshell

用途/分野の例

M85049 backshells are designed to fit the main circular connectors used in our industry.